Sustainable wood-energy management in Cameroon: regional strategies as tools to limit the effects of climate change and support economic development

The national demand for wood energy is 6,560,000 tonnes per year, including 356,000 tonnes of charcoal. This demand for charcoal represents 2.5 million m3 and 12500 ha of natural forest destroyed per year.

This strong pressure on forest cover is at the root of deforestation and the degradation of forest ecosystems, which in turn exacerbates the vulnerability of populations to the effects of climate change.

Wood energy value chain development strategies are being implemented in the East and Far North Regions. The proposed actions are based on a holistic approach that takes all links into account. They address mitigation issues through waste-to-energy conversion, and energy savings and adaptation through reforestation.

The solution partially addresses AbE measures, which have been integrated into a broader strategy linked to sustainable wood-energy management.

Context

Challenges addressed

Harvesting wood for cooking leads to degradation and deforestation of forest areas. This loss of forest cover, coupled with a reduction in the ecosystem services provided by forests, increases the vulnerability of populations to the effects of climate change.

Reducing the pressure on natural forest ecosystems to meet household cooking energy needs is the main ecological challenge.

In social terms, household access to wood energy resources at a reasonable cost remains the main concern. The modernization of wood-energy value chains, which began a few years ago, takes a holistic approach to this issue, with the ultimate aim of satisfying household cooking energy needs while reducing pressure on forest resources and promoting job and wealth creation.

Location

Process

Summary of the process

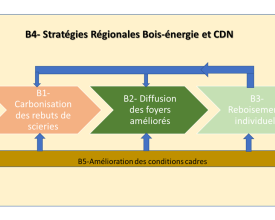

Carbonization of sawmill waste (B1) is a relevant option for reducing pressure on forest cover (B3). Improving household energy efficiency through the use of improved stoves (B2) reduces pressure on forest resources and cuts household expenditure on charcoal or firewood (B1). Individual reforestation (B3) renews the wood resource needed to meet cooking energy requirements (B1) and guarantees the sustainability of forest ecosystems. Facilitating a regulatory framework conducive to the development of wood-energy value chains (B5) is a cross-cutting process that promotes the effective implementation of actions contained in the development strategies drawn up (B4).

Building Blocks

Carbonization of sawmill waste in the Eastern Region

The East Cameroon Region is the country's main forest region. It has 24 wood processing units, generating around 500,000 m3 of scrap wood per year.

The carbonization of sawmill waste has gradually been introduced, given the enormous waste observed in wood processing (material yield of 35%).

Support consisted in organizing and structuring producer groups. Once these producer groups had been legally recognized, efforts were made to sign sawmill scrap agreements with raw material holders, in order to secure the supply of scrap wood to charcoal makers.

The professionalization of charcoal makers in the production chain has focused on the development and implementation of Environmental Impact Notices for charcoal-making activities, and training in improved charcoal-making techniques. It also involved facilitating access to the secure transport documents needed to bring coal to market.

An institutional framework for monitoring the value chain has been set up at regional level, to ensure the improvement of framework conditions for the value chain.

Enabling factors

- The strong involvement of sectoral administrations, with the establishment of a regional platform to guide and monitor the development of the value chain by ministerial decision;

- The willingness of the private sector (owners of wood processing units) to support the carbonization activity by making scrap wood available to charcoal makers;

- The availability of a huge potential of scrap wood;

- The strong participation of local communities thanks to the income generated by the activity.

Lesson learned

- The carbonization of sawmill waste enables UTBs to reduce the incineration of wood waste in the open air and generates financial resources for the local communities involved in the activity;

- the issue of governance in the development of this value chain requires a great deal of attention, particularly with regard to parafiscality, which considerably reduces profit margins;

- the carbonization of sawmill waste is a circular economy model that generates positive effects in terms of avoided deforestation;

- The take-up of Improved Carbonization Techniques is quite good, especially when the technique in question does not require additional investment.

Dissemination of improved cookstoves in the Far North Region

The promotion and use of Foyer Amélioré (FA) is one of the mitigation strategies used by GIZ/ECO Consult to reduce pressure on the timber forest resource in the Far North, as their use reduces household wood consumption and related expenditure.The dissemination and use of Foyer Amélioré Trois pierres (FA3P) and Foyer Amélioré bil-bil in the Far North region since 2015 has enabled a significant and rapid reduction in wood-energy consumption.

Dissemination of the FA3P essentially targets rural and peri-urban areas where wood is the only source of combustion (over 95% of the population depend on it) and building materials are locally available and free of charge, whereas the FA Bil-bil targets rural and urban areas due to the presence of wood-using Small and Medium Enterprises.

Enabling factors

- Dissemination strategy with an organizational structure consisting of 2 coordinators supervising 20 relay trainers;

- Low FA3P construction costs;

- Involvement of partner organizations (Ministère des Forêts et de la Faune (MINFOF), Ministère de l'Environnement de la Protection de la Nature et du Développement Durable (MINEPDED) and Lutheran World Federation-LWF).

Lesson learned

- On a technical level, it should be remembered that in general, before the actual training sessions, awareness-raising must be meticulously carried out to convince people of the merits of making and using FA3Ps.

- On an organizational level, the development and implementation of a new FA dissemination strategy with the deployment in the field of a staff comprising 2 Coordinators supervising 20 Trainer-Relays since November 2018 has enabled a considerable increase in the number of FA3Ps built in households.

- The lack of a financing mechanism for the FA bil-bil of SMEs is an obstacle to the spread of this type of fireplace;

- The FA3P made from clay and dung can last up to 1 year. It can be easily repaired or rebuilt by the users themselves, provided they were trained when the first one was built;

- A verification protocol for the FA3Ps built has been set up to assess and control the quality of the stoves built.

Individual reforestation as an ecosystem-based climate change adaptation strategy

The shortfall between supply and demand for wood fuel in northern regions has led to an ever-increasing degradation of natural resources, a reduction in vegetation cover and a drop in agricultural productivity.

Individual reforestation is carried out on a small scale, on areas ranging from 0.25 to 5 ha. Two main types of reforestation have been implemented: i) agroforestry reforestation, which takes place on cultivated land with the aim of improving farmland productivity despite climate change; ii) forest reforestation, which takes place on degraded land unsuitable for farming, with the aim of restoring degraded forest cover and improving the supply of ecosystem goods and services.

The creation and management of a private plantation follows the main stages of reforestation in dry savannah zones, as described in the GIZ manual on the technical itinerary for reforestation in dry savannah zones in Cameroon.

Beneficiaries were provided with training and technical data sheets for setting up and monitoring individual reforestation plots.

Enabling factors

- Clear land tenure status of areas to be reforested;

- Active involvement of beneficiaries;

- Respect for the silvicultural calendar;

- Compliance with the technical itinerary for reforestation in the dry savannah zone of Cameroon;

- Effective implementation of the post-planting monitoring mechanism.

Lesson learned

- The success of reforestation depends, on the one hand, on compliance with the silvicultural schedule for carrying out each of these activities, and, on the other hand, on compliance with the guidelines set out in the manual on reforestation itineraries in the dry savannah zone of Cameroon;

- The implementation of a monitoring system for reforested sites guarantees good results;

- cattle roaming is one of the causes of reforestation failure in some areas. However, the introduction of measures to secure reforested areas has limited the impact of livestock straying on reforestation.

Regional wood-energy strategies and Nationally Determined Contribution (NDC)

Cameroon's NDC specifies contributions to climate change mitigation and adaptation.

It provides for the reduction of unsustainable fuelwood consumption through, for example, sustainable wood-energy management, improved stoves, and the promotion of methanization and/or butanization in rural areas.

The regional strategies developed are in themselves locally appropriate mitigation measures for wood-energy value chains.

In terms of adaptation, the reforestation actions carried out as part of this solution are fully in line with the NDC's Adaptation Program No. 19 relating to the forestry sector.

The use of improved fireplaces by households, thanks to the wood savings achieved, and the carbonization of sawmill waste, constitute concrete greenhouse gas (GHG) emission mitigation activities. Similarly, restoring the ecosystem functions of degraded areas through individual reforestation is an added value in terms of adaptation. However, although these initiatives are fully in line with the objectives of the UNFCCC, a mechanism for accounting for their contributions at national level is not yet operational.

Enabling factors

- Full involvement of the sectoral administrations ensures that the strategies are well anchored in their respective institutions;

- The existence of a monitoring-evaluation mechanism within the project to measure progress and report on results in terms of avoided CO2 emissions and avoided deforestation;

- Availability of sustainable financial resources to pursue activities;

- The appropriation of tools and methods for accounting for avoided GHG emissions by the various players involved.

Lesson learned

- An effective MRV (Monitoring, Reporting, Verification) system needs to be put in place at national level to monitor and capitalize on the results of implementing regional wood-energy strategies;

- Exploring the possibilities offered by climate financing for GHG emission reduction initiatives can help ensure the sustainability of funding for these strategies;

- The adaptation benefits generated by reforestation are difficult to assess accurately in the short term.

Improving framework conditions for the development of value chains

Multi-stakeholder consultation frameworks have been set up to guide and monitor the development of wood-energy value chains in the target regions.

In the Eastern Region, a regional platform has been set up by the Minister in charge of forests and wildlife, under the chairmanship of the Regional Governor.

In the Far North, a regional wood-energy unit (CRBE) has been set up.

These consultation frameworks are held every six months, and serve as a forum for taking stock of progress in the value chains concerned, as well as formulating guidelines for their smooth operation.

The strategic direction of the wood-energy value chains, embodied in the strategy documents drawn up, is the result of a consultation process involving the various stakeholders meeting within these consultative bodies.

The resolutions resulting from these meetings have enabled certain advances to be made, namely: i) the definition of a regulatory framework for the production and marketing of wood-energy; ii) the development and validation of guideline standards for the management of dryland forests.

Enabling factors

- Raising awareness among political decision-makers of the importance of the wood-energy sector;

- Good participation of the various value chain players concerned in the meetings called;

- Good follow-up of the platform's recommendations by the technical secretariat set up.

Lesson learned

- Funding for meetings of the CRBE in the Far North and the Plateforme Régionale Bois énergie in the East must be included in the budgets of local forestry departments to ensure the sustainability of these discussion forums;

- The involvement of all categories of stakeholders in the various links of the wood-energy value chains has enabled us to propose regulatory texts that are adapted to reality and conducive to the development of these value chains;

- Monitoring the evolution of wood-energy value chains within the framework of the CRBE or the Eastern platform, has helped to improve governance in the management of the value chains concerned.

Impacts

On the socio-economic front

- The production of 15,000 tonnes of charcoal from sawmill waste in the Eastern Region from 2018 to 2020 generated sales of 776.5 million FCFA or 1,183,766 Euro.

- Around 400 direct jobs created by the sawmill waste carbonization activity.

- The distribution of 33,962 improved three-stone fireplaces (FA3P) to households has enabled them to save 2,068,616,198 FCFA (3,153,585 Euros) on wood purchases to meet their cooking energy needs.

On the environmental front

- the carbonization of sawmill waste over the three years avoided the emission of : 228,765.4 Tonnes equivalent (Teq) CO2, or 901 ha of natural forest preserved.

- The distribution of FA3P avoided the emission of 50,474.2 Teq CO2. The wood savings generated by the use of FA3Ps have enabled the preservation of 4,805.1 ha of dry forest.

- From 2016 to 2020, 50.97 ha of private reforestation were carried out by local people to restore and/or improve the ecosystem functions of degraded areas.

- 10,741.67 ha of forest reserves transferred to the Communes of the Far North region are currently being managed.

Beneficiaries

- 237,734 people benefiting from FA3P ;

- Communes in the Far North Region ;

- 434 charcoal producers ;

- 60 private landowners benefiting from reforestation support;

- 1,200 coal workers;

Sustainable Development Goals

Story

ERIC NGONO: the motivational charcoal maker.

In the past, in the locality of Abong-Doum, located in the East Cameroon Region, the wood scraps generated by the local Unité de Transformation de Bois (UTB) were incinerated in the open air. During a visit to Libongo in eastern Cameroon, Éric had his first glimpse of the charcoal-burning activity carried out around the UTB of the Société d'Exploitation Forestière et Agricole du Cameroun (SEFAC) by a group of charcoal-burners supported by GIZ.

As soon as he returned to the village of Abong-Doum, he approached the Société de Transformation de Bois et de Commerce (STBC) company to take advantage of the wood scraps for carbonization, thus limiting the wastage that used to occur.

Éric thus put himself at the head of a group of charcoal makers who started up the carbonization activity without any prior training.

The opportunity presented by the installation of a second UTB in the village of Abong-Doum by the company DINO &FILS was seized by the group of charcoal burners led by ERIC, who approached the GIZ for support in structuring and professionalizing their group of charcoal burners.

As a result, the group has grown from around 20 to 150 members, with an average monthly production of 4,000 bags of coal (170 tonnes). Thanks to Eric's impetus, over 100 families in Abong-Doum depend on the charcoal-making activity to meet their economic needs.

The Goupe d'Initiative Commune (GIC) headed by Eric has all the official approvals required for the carbonization business. It is also registered with the authorities as a coal exporter.