Engineering the Production of Compostable Menstrual Pads Using Plant-Based Fiber as the Main Absorbent Core

This initiative is part of the Sparsa Solution, a Nepali non-profit organization that locally produces and distributes compostable menstrual pads, which have an absorbent core made from banana fiber.,

Conventional fluff pad production machines are either manual-making them labor-intensive and unhygienic-or fully automated, which requires high upfront investment and is often incompatible with eco-friendly materials. To overcome these challenges, engineers from NIDISI, Sparsa, and Grit Engineering developed a semi-automatic, low-cost system tailored to local Made in Nepal.

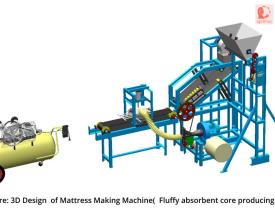

Built with limited resources, the system produces 3,500–4,000 pads per day and includes:

- A paper shredder for uniform fiber cutting;

- A custom mattress-making machine for the fluffy absorbent core;

- A modified pad assembly machine that seals different layers using ultrasonic sealing and compostable glue.

This setup enables safe, small-scale production while reducing plastic waste and supporting menstrual health for the benefit of women and the environment.

Context

Challenges addressed

Environmental: One key challenge was sourcing compostable, non-plastic top and bottom layers. After extensive research and testing, we identified safe, certified materials that significantly reduce plastic pollution. We also aimed to reduce reliance on imported synthetic components by using locally available banana fiber, promoting a circular economy.

Social: Manual pad-making methods are often unhygienic and labor-intensive. Our semi-automatic system ensures cleaner production while creating dignified local jobs. By training unskilled workers and setting up micro-factories, we empower rural communities and improve access to safe menstrual products.

Economic: Most fluff pad machines are either too expensive or unsuitable for eco-materials. We developed low-cost, user-friendly machinery—including a custom fluffy absorbent core production machine and a modified layer assembly system—that can be locally replicated in resource-limited settings, reducing startup costs and dependency on foreign technology

Location

Process

Summary of the process

This four-part solution outlines a step-by-step approach to producing compostable menstrual pads using locally sourced plant-based materials.

The process begins with setting up a functional factory layout (Building Block 1) that defines machine placement, energy access, material flow, hygiene zoning, and workspace organization. This layout ensures smooth operation and efficient coordination between units. In Building Block 2, plant-based paper made from banana fiber is processed into fluffy absorbent cores using a custom-designed, low-cost machine. This machine was developed from scratch, with detailed technical guidelines, local fabrication options, and CAD files to support replication. Building Block 3 focuses on the pad assembly process. Top and bottom roll materials are fed into a modified semi-automatic machine, while the absorbent core is manually inserted via a synchronized conveyor. The layers are sealed using ultrasonic bonding, shaped, sterilized, and then packaged. Building Block 4 focuses on the raw material used for compostable pad production and maintenance, and the safety protocol for the machine.

Together, these blocks form a replicable, plastic-free production model that strengthens menstrual health access, reduces plastic pollution.

Building Blocks

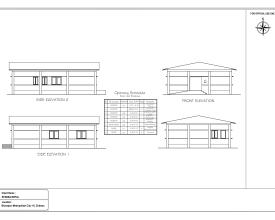

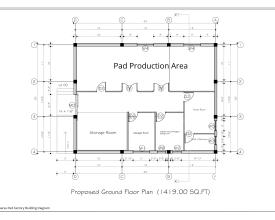

Comprehensive Factory Layout and Workflow of Menstrual Pad Production Unit

Factory Layout Overview:

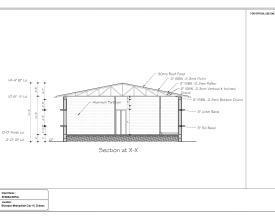

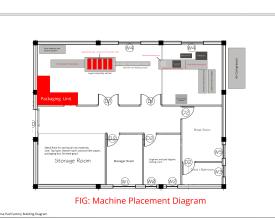

The sanitary pad production unit is located near an urban area to ensure easier access to distribution channels, skilled labor, and transport networks. The factory is built with concrete walls and insulated galvanized tin sheet roofing, providing durability and heat protection during warmer seasons.

- Total Area: 1,420 sq. ft

- Production Scale: Semi-scale

- Daily Output: 3,000 pads

- Key Areas: Raw material storage, production floor, office, break room, restroom, and an internal lab for testing pads

For visuals of the layout and machine placement, please refer to the gallery attached to this block.

Step-by-Step Production Workflow

- Raw Material Collection

- Banana Fiber Paper Shredding

- Fluffy Absorbent Core Formation

- Layer Assembly and UV Sterilization

- Packaging and Storage

Note: Hygiene is a top priority. The factory adheres strictly to national hygiene standards and follows clear internal protocols to ensure product safety at every stage of production. For further insights on hygiene practices, see Solution name “Defining a Good Menstrual Pad: A User-Centered R&D Process in Nepal.”

Additional Documents Available in this Block:

- Detailed factory layout and production/material flow (PDF)

- Energy consumption overview (PDF)

- Cost estimation for setting up the factory (PDF)

Enabling factors

- Access to Skilled and Committed Local Teams: A key enabler was working with a motivated local team of engineers, technicians, and community members who co-developed the layout, machinery, and production processes.

- Collaborative Engineering Partnerships: Close collaboration between Sparśa, NIDISI, and Grit Engineering ensured a practical and efficient setup tailored to compostable pad production using banana fiber.

- Availability of Local Building Materials: Using locally available materials for construction helped reduce costs, avoid delays, and ensure context-appropriate building design.

- Proximity to Urban Infrastructure: Choosing a location close to electricity supply lines, road access, and labor pools helped streamline setup and operational logistics.

- Commitment to Hygiene and Quality Standards: The integration of hygiene protocols and on-site testing facilities ensured product safety and regulatory compliance from the beginning.

- Hands-On Prototyping and Iteration: The flexibility to prototype machine layouts and factory flow on-site allowed for rapid problem-solving and process improvements.

Lesson learned

- Start with a Leased Facility

When budgets are limited, leasing a space is a more flexible and cost-effective option. Once the product gains traction and operations stabilize, you can invest in building a permanent facility. - Select Your Location Wisely: Choose land with access to government utilities like water and electricity. Avoid polluted areas or sites near chemical factories to meet hygiene standards. Engaging with local community members early can help prevent land-use conflicts later.

- Involve Professionals from the Start: Even for small buildings, consulting architects or engineers is essential. Key aspects like ventilation, lighting, and structural durability are often overlooked without expert input.

- Maintain Clear Communication with Contractors: Regular updates and site visits help ensure that the work follows your expectations and timeline, reducing delays and misunderstandings.

- Plan the Electrical Setup Around Machines: Understand your machines’ power needs (single-phase vs. three-phase) before finalizing layout. Proper planning avoids costly rewiring or power mismatches during installation.

- Build Local Technical Support Networks: Having a reliable local metalworker or technician on standby can make a big difference when small repairs or adjustments are needed—keeping your production on track.

Fluffy Absorbent Core Making: Machinery Overview, Detail process explanation, 3D Models

This block explains how processed banana fiber sheets are transformed into fluffy, absorbent cores using a custom-built semi-automatic machine. These absorbent cores form the middle layer of compostable menstrual pads.

The machine operates through a carefully sequenced, semi-automated process designed to ensure consistent quality and efficiency, especially in low-resource settings:

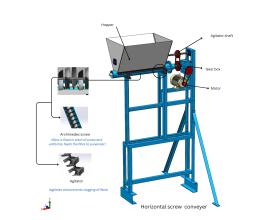

- Shredding: The process begins with a shredder that cuts banana fiber sheets into small, uniform pieces using rotating blades. This ensures consistency for the next stages.

- Feeding and Agitation: Shredded paper is fed into a hopper fitted with an Archimedes screw and an agitator. The screw provides a steady feed into the pulverizer, while the agitator prevents clogging.

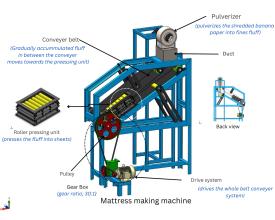

- Pulverizing and Fluff Core Formation: Inside the high-speed pulverizer, the paper is broken down into fine fluff. Centrifugal air motion spreads the fluff evenly onto a confined moving belt.

- Compression into Sheets: The evenly distributed fluff is compressed between two belts using a series of rollers. This binds the fluff into continuous absorbent sheets.

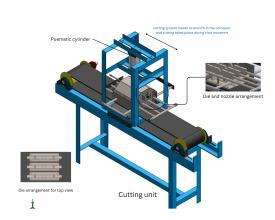

- Cutting to Size: The sheets are then moved by a conveyor to a cutting unit powered by an air compressor and controlled by a universal timer. This unit cuts the sheet into the required absorbent core dimensions.

- Trimming and Fluff Recycling: Dies press the sheet into shape, while surrounding air nozzles blow away excess fluff. This loose material is collected via suction and recycled for reuse.

This process enables clean, efficient, and uniform absorbent core production, using locally available materials and technology appropriate for semi-scale operations.

Additional Resources for Replication:

- PDF: Details of Working Mechanism and Operation Procedure

- PDF: Electrical Connection Diagram of Cutting System

- CAD file: Mattress Making Machine – GrabCAD link

Enabling factors

- Strong Collaboration with Local Engineering Workshops

Building a custom machine required close cooperation with skilled metalworkers and engineers who could adapt designs, prototype components, and iterate based on field feedback. - Clear Technical Specifications and Planning

Developing a detailed understanding of each process step—shredding, feeding, pulverizing, sheet formation, and cutting—was essential for translating needs into machine design. - Availability of Banana Fiber Paper

A consistent and quality supply of processed banana fiber sheets was necessary to ensure the performance of the machine and the fluff core output. - Reliable Power Supply and Air Compression System

The machine requires stable electricity (including high-speed motors) and a safe, well-regulated compressed air system for the cutting unit and fluff recycling. - Prototyping Mindset and Flexibility

The development process included trial-and-error phases, requiring patience, a flexible approach to adjustments, and ongoing testing to achieve the desired fluff consistency and hygiene standards.

Lesson learned

- Set Clear Agreements with Machine Builders: A well-defined contract is essential. It should cover machine capabilities, materials to be used, budget constraints, delivery timelines, mechanisms for addressing delays, and any expected custom modifications.

- Maintain Frequent Communication and Site Visits: Regular check-ins with the fabrication team—both virtual and in-person—help ensure the machine is built as per design, and enable fast troubleshooting when issues arise.

- Expect Delays and Use Time Strategically: Machine fabrication often takes longer than anticipated. During such delays, focus on parallel tasks like training, raw material procurement, or factory setup to avoid bottlenecks later.

Technical Lessons from Using the Custom Machine

- Air-Compressed Cutting System: A Safety Concern: The air-compressed cutting mechanism proved complex and posed safety risks due to potential pipe disconnections under high pressure. A roller-based cutting system would be simpler and safer for future designs.

- Dust Management is Critical: Banana fiber, when pulverized, creates fine airborne particles. Combined with high-pressure air, this generates a lot of dust. Effective ventilation and dust control systems are essential for safe, hygienic operation.

- Custom Machine Development Requires Patience: While tailored machines offer precision and innovation, the design process demands strong technical understanding, problem-solving, and patience through trial-and-error development cycles.

Layer Assembly and Construction Process of Compostable Menstrual Pads

We purchased a semi-automatic pad assembly machine and later modified it to suit our specific process. Standard machines are typically designed for industrial-scale use with plastic-based materials and continuous roll inputs. Since we work with natural banana fiber absorbent cores, which are not in roll form, we had to adjust the machine to make it work with our setup.

The top and bottom layers (non-woven cotton and PLA-" bioplastic made with Poly Lactic acid material which is compostable layers" )come in rolls. These rolls are installed on the machine. In the middle, we manually place our pre-cut fluffy absorbent cores onto a moving conveyor belt. The machine is equipped with sensors and a timing system that aligns everything.

As the materials move through the machine:

- The three layers are pulled together

- A roller system compresses and seals the pad using ultrasonic sealing

- The pad is then shaped and cut

- After this, each pad passes through a UV-C light tunnel for sterilization

Finally, we manually apply the adhesive and pack the pads for distribution.

These modifications allow us to work with eco-friendly, compostable materials while still maintaining a semi-automated workflow. It’s not perfect, but it works—and it’s much more suitable for small-scale, low-resource settings than fully automated systems designed for plastic pads.

For a detailed understanding of the technical specification

- PDF titled “Detailed Explanation of layers assembly system”

- PDF titled “Technical Parameter Layers Assembly Machine”

Enabling factors

- Consistent Raw Material Quality: The machine performs best when the top and bottom layers are delivered as uniform rolls. The top layer (non-woven cotton) and bottom layer (PLA-"Poly Lactic acid" bioplastic) should both be approximately 20–30 cm wide, with consistent thickness and tension to avoid jamming during feeding. Materials that are too stiff, too stretchy, or too thin may not seal properly.

- Absorbent Core Dimensions: The banana fiber absorbent cores need to be pre-cut to a fixed length and width so they fit exactly within the sealing area of the machine. If the core is too thick, it may cause misalignment or sealing errors. In our case, cores are around 3–4 mm thick.

- Proper Electricity Supply: The machine requires single-phase electricity with a stable voltage. Power fluctuations can affect sensor calibration, roller pressure, and sealing consistency. Installing a voltage stabilizer is recommended if your grid is unstable.

- Operator Familiarity with Materials: Since the core is manually placed, the operator needs to be trained to recognize and align materials correctly, especially when working with non-standard, eco-friendly components.

- Machine Setup and Calibration: Sensor positions, roller pressure, and timing need to be calibrated for the specific material combination. Minor adjustments are often required when switching to a new roll or absorbent core batch.

Lesson learned

- Test the Machine with Your Own Materials Before Shipping: When importing a machine—especially one that requires custom modifications—it’s essential to maintain regular contact with the supplier. Ask for photo and video updates throughout the build process, and if possible, visit the site for in-person testing using your actual raw materials. This helps catch issues early and ensures the machine functions as expected in your context.

- Always Test Raw Materials Before Buying in Bulk: Materials that work in theory may not work in practice. We learned it’s worth requesting samples from multiple suppliers and running small-scale tests on the machine before committing to large orders. This prevents mismatches, production delays, and waste.

- Sort Out Import Documents in Advance: If the machine is being shipped internationally, make sure all legal and customs paperwork is handled while the machine is still in production. Waiting until the last minute can result in costly delays at the border once the machine is ready to dispatch.

Machine & Material Specifications with Safety and Maintenance Protocols

This section outlines comprehensive technical details regarding the raw materials used in the manufacturing of Sparsa sanitary pads. It also includes specifications for each material layer, associated machine requirements, maintenance considerations, safety protocols, and final packaging standards. This information is critical for ensuring production quality, material traceability, and process control.

The three functional layers—top, absorbent core, and barrier—are assembled using a pad assembly machine (refer to Building Block 3 for detailed information). After assembly:

- Adhesive is applied manually

- Pads are tri-folded

- Each pad is packed individually using a compostable pouch

Additional Resources for Replication:

- PDF: Details of information about the Raw materials used for compostable pad production

- PDF: Details of information about machine maintenance and safety protocol

Impacts

Our solution creates meaningful social, economic, and environmental impact in rural and semi-urban communities in Nepal.

- We have established a semi-scale pad production unit that provides employment and income for 10+ local workers, including women from marginalized backgrounds, in roles ranging from machine operation to leadership.

- Through hands-on training, we have built technical capacity in machinery use, maintenance, production control, and hygiene management—skills rarely accessible to rural workers.

- By offering compostable, plastic-free menstrual pads, we increase access to safe, dignified, and affordable menstrual health products for communities that previously relied on expensive or unsafe alternatives.

- Our use of banana fiber, an agricultural by-product, reduces waste and plastic pollution. By replacing plastic-based Superabsorbent polymer(PLA)- liquid absorbent material and layers with biodegradable materials, we help decrease long-term environmental burden and support healthier soil ecosystems post-disposal.

- The localized factory model strengthens community ownership, encourages local procurement, and reduces dependency on imported products.

- The project promotes gender equity, highlights women’s roles in technical fields, and offers a replicable path toward circular, inclusive, and climate-resilient manufacturing.

Beneficiaries

Local Women and Girls: Especially in rural and underserved areas-now have access to affordable and hygienic menstrual products. This will significantly enhance their health, dignity, and ability to participate fully in education, work, and daily life.

Sustainable Development Goals

Story

Never Giving Up: The Journey to Building a Game-Changing Machine:

Two determined engineers from NIDISI set out with an ambitious goal—to build a machine that could transform banana fiber into soft, absorbent sheets for eco-friendly sanitary pads. But this mission wasn’t only about technology. It was about creating sustainable menstrual health solutions that could reach the most remote communities. To succeed, the machine had to be compact, affordable, semi-automated, and efficient enough for small-scale decentralized production. But existing machines posed a problem. Those available in India and China were either too manual and slow or fully automatic but too expensive and large. Nothing met their unique needs.

So, they decided to build one from scratch.

In collaboration with GRIT Engineering—renowned for innovative machine design—they took on a challenge that had no precedent. Even for GRIT, this was new territory. Banana fiber, though sustainable, proved incredibly difficult to work with. Its soft, irregular structure made it hard to feed and spread evenly. Pulverizer speed, mesh type, and feeding consistency were deeply interconnected—adjusting one variable affected the whole system.

Three months passed. Then six. Then nine. Still no perfect sheet. The cutting system also failed to deliver clean results.

But the team didn’t quit. Every failed attempt became a lesson. Every setback moved them closer. They pressed on. A breakthrough came when Sworup Raj Poudel, NIDISI Nepal’s Technical Engineer, who had been guiding the process remotely, decided to join in person. He introduced a critical change—feeding the machine with shredded banana paper instead of loose fiber. It was denser, more uniform, and fed more consistently. For the first time, the machine produced a clean, uniform sheet.

Shortly after, Florian Didier, NIDISI’s EU Technical Lead, joined the workshop. With his deep expertise in natural fibers, he helped fine-tune the system—improving sheet uniformity and optimizing the cutting mechanism.

Finally, after nearly a year of hard work, the prototype stood completed—a fully functional, purpose-built machine. It represented more than just hardware. It embodied creativity, resilience, and a deep commitment to impact.

This machine is more than metal and motors. It symbolizes innovation driven by purpose. Built for underserved regions,

To every changemaker out there:

Real innovation is born in persistence. This team proved that. They never gave up.